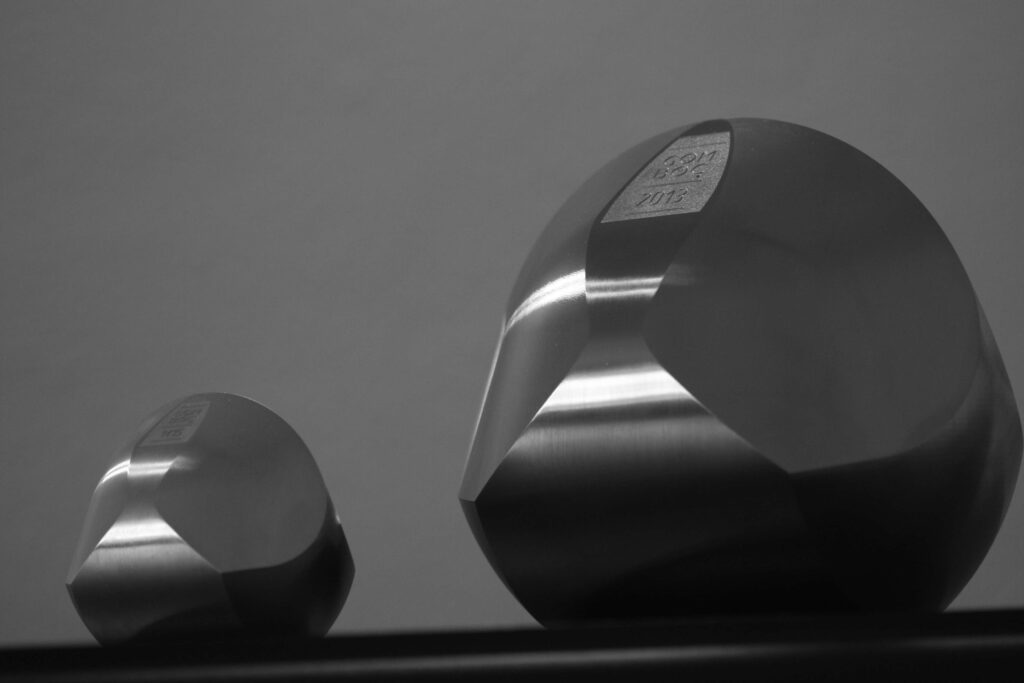

The Gömböc is the world’s first homogeneous, self-righting shape (it even has a Guinness World Record). First hypothesized in 1995 by the Russian mathematician Vladimir Arnold, it wasn’t until 2007 that Hungarian mathematicians Gabor Domoks and Peter Varkonyi created the first computer model, and then a physical model of a Gömböc (New York Times). What makes the Gömböc such a unique shape is that it only has 2 equilibrium points (one stable and one unstable). This makes it so that no matter what position you put the Gömböc in, it will right itself to be in its stable equilibrium position. More importantly, this isn’t done through any hidden tricks like a weighted lower half. The shape has uniform density, so its “self-righting” ability is purely thanks to the mathematical properties of its shape (Gömböc.eu).

https://gomboc-shop.com/

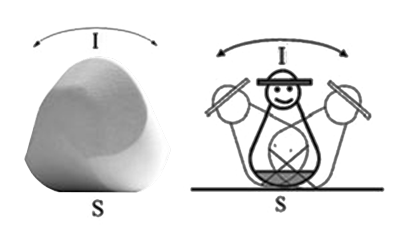

Mathematically, an equilibrium point is defined as a place where the derivative of the potential energy of a shape is zero. For an equilibrium point to be “stable”, it means that the second derivative of the shape’s potential energy at that point is positive, whereas an “unstable” equilibrium point has a negative second derivative of potential energy (The Action Lab).

In the Gömböc, the stable equilibrium point is the crest of the cylindrical side, and its unstable equilibrium point is the sharper ridge at the “top”. In theory, the Gömböc could be balanced on its unstable equilibrium point, but the negative second derivative of PE for that point makes it so that any slight variation from that point will lead the shape away from that equilibrium and toward the “stable” equilibrium point – hence the names “stable” and “unstable”.

https://gomboc.eu/en/gomboc-information/

Given the intricate mathematical nature of this object, to create the physical model of this shape Domoks and Varkonyi had to send it to a special manufacturer in Budapest. According to Wikipedia, Gömböc’s have a shape tolerance of 0.001. For context, this means that a Gömböc that is 10cm across at its longest part, can only be off from the mathematical model of a Gömböc by 0.1mm. Therefore, the Budapest manufacturer not only had to recreate the computer model out of a uniform-density material, but it also had to satisfy this level of precision. Because of these difficult manufacturing specifications, Gömböcs online are priced at a minimum of $100 (Gömböc.eu).

With all of this in mind, we think it would be a very exciting challenge to dive deeper into the math behind this shape and try to create our very own Gömböc!

Gömböc Prototyping

The first stage of our project was to do a proof-of-concept 3D-print of a Gömböc. Given that the formula for a Gömböc isn’t openly available, and that none of us had ever 3D-printed before, we decided to use a 3D model of a Gömböc we found online which was reverse-engineered by Thingiverse user Rhiffsta.

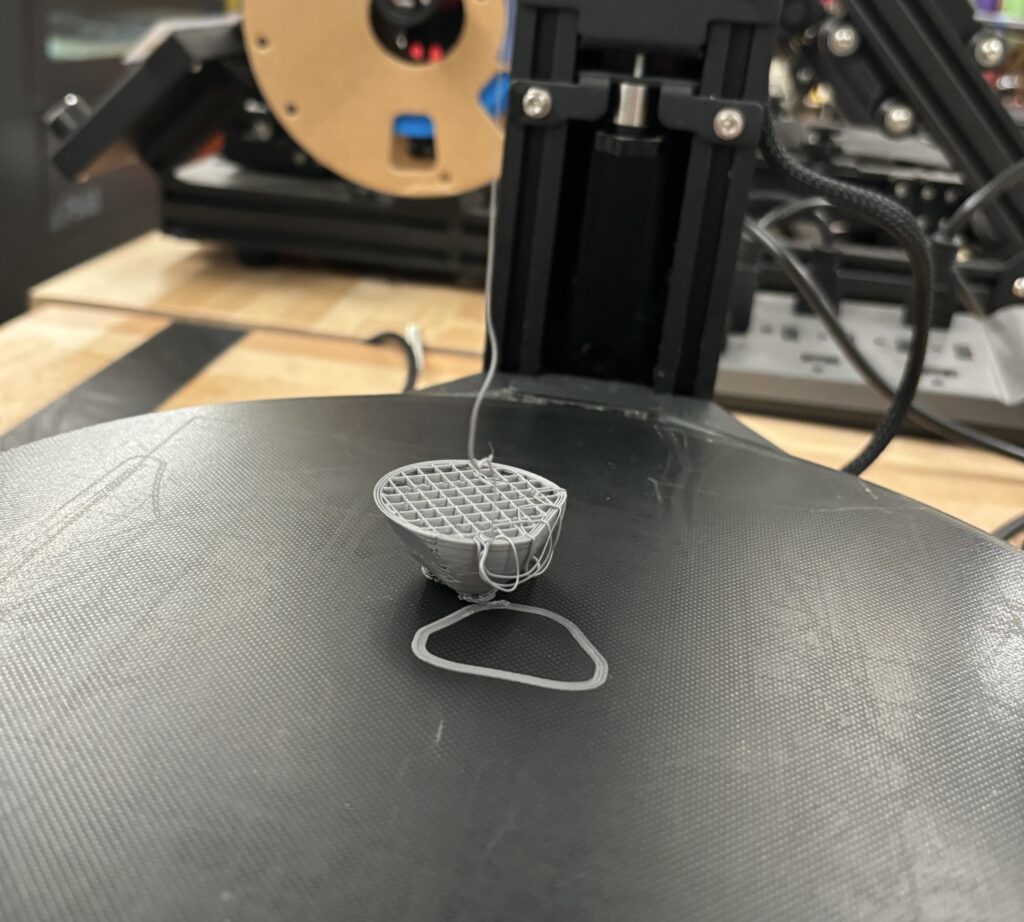

We began our prototyping by trying to use the FLSUN printers. Unfortunately, we instantly ran into issues with our model, as our print kept getting unstuck from the base of the printer. We attempted to resolve this by first changing the infill percentage from 100% to 30%, sacrificing uniform density, but hoping that the use of less material per layer would make it harder for the 3D printer to accidentally move the print. When this didn’t work, we additionally tried changing the layer height from 0.1 mm to 0.2mm to 0.3 mm, sacrificing the print’s resemblance to an actual Gömböc to try and at least get a successful print. This change seemed quite promising, as the print got quite far in the process, but about halfway through the print, the Gömböc got unstuck once again. Below is a picture of this print once it failed:

Despite the failed print, this process allowed us to learn how to 3D print, get comfortable with the software and materials, and figure out how changing different parameters in the 3D design can affect the success of our build! One issue we noticed with using the LSUN printers, is that the supports attached to the Gömböc are super hard to remove, which could cause us to damage the integrity of the shape even more. Because of this, as well as the other issues we ran into, we’re thinking of trying to use more advanced 3D printing methods and equipment to try and print the Gömböc next week.

Advanced 3D Printing

After doing more research on the 3D printers available to us in the MakerSpace, we decided that we wanted to use the Powder Printer for our Gömböc. Not only is this printer more accurate than the LSUN, but it also doesn’t use supports, and has a super high print success rate due to the way it creates the print. Therefore, we wouldn’t have to worry about the print getting unstuck from the printer base! However, due to a big backlog of prints, we were unable to access the powder printer during our allotted work time.

Therefore we decided to shift strategies and try using the resin printer instead. With the resin printer, the print would have a similar level of quality and detail as if it had been printed with the powder printer. Furthermore, even though the resin printer does use supports, they are expected to come off super easily during post-processing, which means the shape shouldn’t be affected much by the making process. When we tried using the resin printer though, it would not detect the printer tank. After unsuccessfully trying to fix this detection issue with a steward for quite some time, we decided to try and run the print anyways, as the tank was clearly in the printer. Despite that, the tank detection problem ended up being a hard lock, and we were unable to print our model using the resin printer.

Ultimately, with these two printers off-limits, we decided to turn to the carbon fiber printer. Despite having sturdier supports than the resin printer, this printer would still provide us with a much higher quality print than the LSUN and the print’s supports would be easier to take off – not to mention the printer has a much higher success rate. Using this printer, we were able to print out the 3D model of the Gömböc!

Carbon Fiber Gömböc

Here is the Gömböc we created using the carbon fiber printer:

Overall, the print was fairly successful – it looks like a Gömböc and has relatively smooth edges! But, given that we made our Gömböc small (around 2cm long), as well as the fact that we didn’t ensure uniform density, it doesn’t work perfectly. As you can see below, it does self-right itself sometimes,

But other times, it simply finds another equilibrium point,

Even so, I think that our project can be considered a success! We not only learned how to 3D print, but we also got to experience using and troubleshooting all of the advanced 3D printers and got our own Gömböc-looking piece of carbon fiber!

Project Extensions

Looking forward, there are quite a few ways we think we could build upon this project, and get closer to recreating a Gömböc that satisfies all the mathematical properties it’s meant to have.

Firstly, we’d like to use the powder printer to create a larger Gömböc. Not only would this make it easier to satisfy the Gömböc’s very small shape tolerance, but it would also give us a cleaner print with no supports, and therefore a much smoother surface.

Secondly, we want to try and use our new Gömböc model to create a resin mold for it, and then try casting it out of epoxy resin. This way, we would satisfy the uniform density constraint of a Gömböc.

Hopefully, through these two extensions, we can create an actual Gömböc! We’ll make sure to keep this post updated if we do decide to go through with these suggestions.

Leave a Reply